Choosing the right valve size can be a daunting task, especially when incorrect sizing leads to poor system performance, increased energy costs, or even system failure. For businesses relying on valves for heating systems, plumbing, or industrial applications, these issues can result in costly downtime and lost revenue. The solution? Understanding valve sizing and its importance in ensuring optimal performance. This article will guide you through the essentials of valve sizing, helping you make informed decisions for your business.

Valve sizing refers to the process of selecting the correct valve dimensions to ensure proper flow control, pressure regulation, and system efficiency. It involves understanding factors like flow rate, pressure drop, and valve type to match the valve’s capacity with the system’s requirements.

Ready to dive deeper? Let’s explore the key aspects of valve sizing and how it impacts your operations.

What Are the Sizes of Rotary Valves?

Rotary valves are widely used in various industries for controlling the flow of liquids, gases, and powders. Their sizes are determined by the diameter of the valve’s inlet and outlet ports, which directly affect the flow rate and pressure drop. Common sizes for rotary valves range from 1/2 inch to 24 inches, depending on the application.

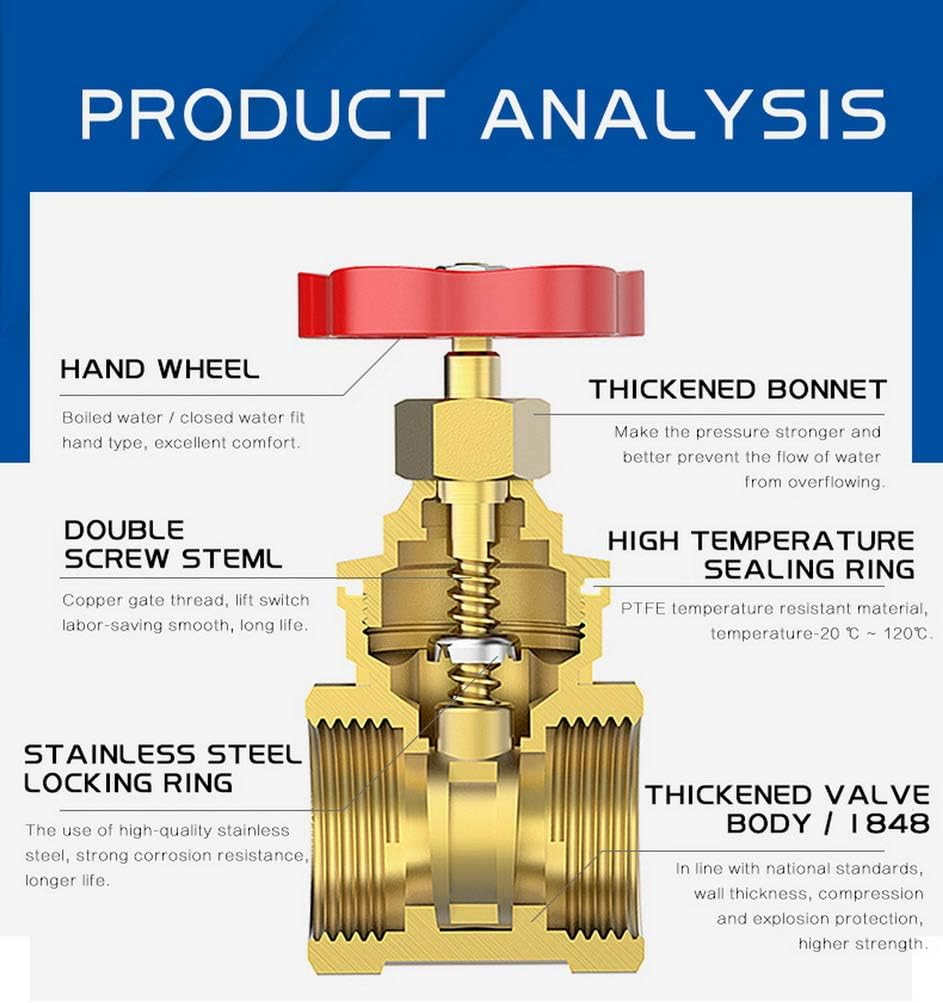

For example, smaller rotary valves (1/2 inch to 2 inches) are often used in residential heating systems or light industrial applications, where precise flow control is required. Larger rotary valves (4 inches to 24 inches) are typically used in heavy industries, such as oil and gas, where high flow rates are necessary. When selecting a rotary valve, it’s crucial to consider the valve parts name and their functions, such as the rotor, housing, and seals, to ensure compatibility with your system.

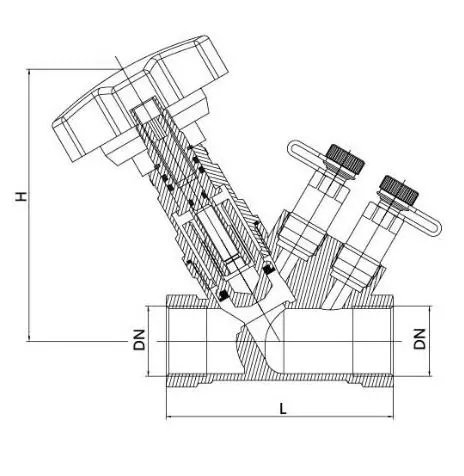

Understanding the valve parts diagram can also help you visualize how the valve operates and how its size impacts performance. By choosing the right size, you can avoid issues like excessive pressure drop, which can strain your system and reduce efficiency.

What is Valve Nominal Size?

Valve nominal size (NPS or DN) is a standardized measurement used to describe the approximate inner diameter of a valve. It helps simplify the selection process by providing a common reference point for manufacturers and buyers. For instance, a valve with a nominal size of 2 inches (NPS) or 50 mm (DN) will fit piping of the same nominal size.

However, it’s important to note that the nominal size doesn’t always match the exact dimensions of the valve. For example, a 2-inch valve might have an actual inner diameter of slightly more or less than 2 inches, depending on the design and manufacturing standards. This is why understanding the parts of valve assembly, such as the body, seat, and stem, is essential for ensuring a proper fit.

When selecting a valve based on nominal size, consider factors like flow rate, pressure, and the type of fluid being transported. A mismatch between the valve size and the system requirements can lead to inefficiencies, such as cavitation or erosion, which can damage the valve parts in the engine or other critical components.

What is the Size of Gate Valve?

Gate valves are commonly used for on/off control in pipelines, and their size is determined by the diameter of the valve’s bore. Standard gate valve sizes range from 1/2 inch to 24 inches, with larger sizes typically used in industrial applications. The size of a gate valve directly impacts its flow capacity and pressure drop.

For example, a 2-inch gate valve is suitable for residential or light commercial applications, while a 12-inch gate valve might be used in water treatment plants or oil refineries. When selecting a gate valve, it’s important to consider the control valve parts and functions, such as the gate, seat, and stem, to ensure smooth operation and longevity.

Additionally, understanding the parts of valves in the heart of your system can help you identify potential issues early. For instance, a gate valve that’s too small for your system can cause excessive pressure drop, while one that’s too large may lead to poor flow control and increased costs.

Summary

Valve sizing is a critical aspect of system design and operation, impacting everything from flow control to energy efficiency. By understanding the sizes of rotary valves, the concept of nominal size, and the dimensions of gate valves, you can make informed decisions that enhance your system’s performance and reliability. Whether you’re dealing with valve parts name, valve parts diagram, or parts of valve assembly, choosing the right size ensures optimal functionality and longevity.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.