When it comes to valve performance, the stem plays a crucial role. A faulty or poorly designed stem can lead to leaks, operational failures, and even costly downtime. For businesses relying on valves for their operations, such issues can disrupt workflows and result in significant financial losses. Understanding the stem’s function and choosing the right type can prevent these problems, ensuring smooth and efficient valve operation. This article dives deep into the valve stem, its types, and why it matters.

The stem of a valve is a critical component that connects the actuator to the valve disc or plug, enabling the control of fluid flow. It is responsible for transmitting motion to open or close the valve, ensuring proper regulation of liquids or gases.

Curious to learn more about how the stem impacts valve performance and the different types available? Keep reading to explore the details and make informed decisions for your valve needs.

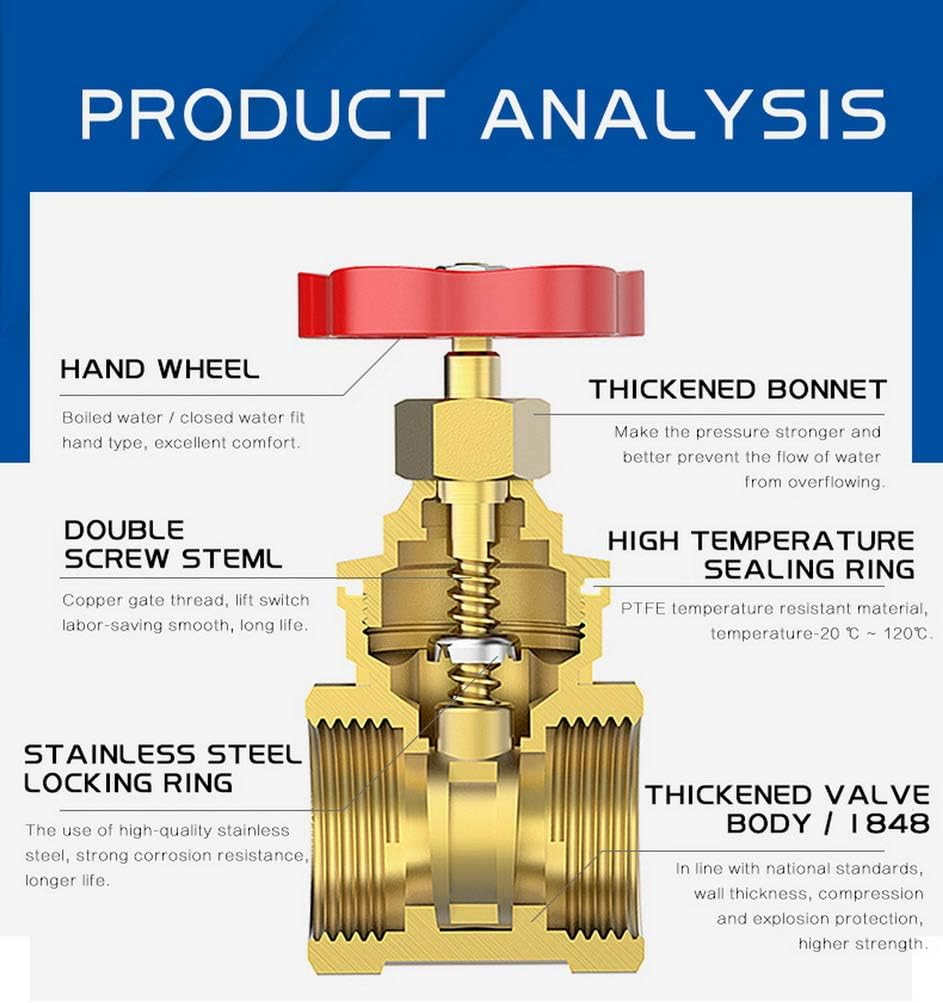

What is a Gate Valve Stem?

A gate valve stem is a key part of a gate valve, which is widely used in plumbing and industrial applications. The stem is the rod that moves the gate (the disc) up and down to control the flow of fluid. When the stem is turned, it either raises the gate to allow flow or lowers it to stop the flow. The stem is typically threaded, and its movement is controlled by a handwheel or an actuator.

Gate valve stems are designed to withstand high pressure and temperature, making them suitable for demanding environments. They are often made from durable materials like stainless steel or brass to ensure longevity and reliability. The stem’s design and material are crucial because any failure in the stem can lead to leaks or complete valve malfunction. For industries like oil and gas, water treatment, or manufacturing, a reliable gate valve stem is essential for maintaining operational efficiency.

What are the 2 Types of Gate Valves?

Gate valves are primarily categorized into two types based on their stem design: rising stem gate valves and non-rising stem gate valves. Each type has its unique features and applications.

- Rising Stem Gate Valves: In this type, the stem moves upward as the valve is opened. The stem’s threads are outside the valve body, and the handwheel rises with the stem. This design provides a visual indication of the valve’s position, making it easier to determine whether the valve is open or closed. Rising stem gate valves are commonly used in above-ground installations where space is not a constraint.

- Non-Rising Stem Gate Valves: Here, the stem does not move upward. Instead, the gate moves up and down while the stem remains in place. The threads are inside the valve body, and the handwheel does not rise. This design is ideal for underground or confined spaces where vertical movement is restricted. Non-rising stem gate valves are often used in pipelines and systems where space is limited.

Both types have their advantages, and the choice depends on the specific application and installation requirements.

What is the Difference Between a Gate Valve Non-Rising Stem and Rising Stem?

The primary difference between a non-rising stem and a rising stem gate valve lies in the movement of the stem and the visual indication of the valve’s position.

- Rising Stem Gate Valves: These valves provide a clear visual cue of the valve’s status. As the stem rises when the valve is opened, it is easy to see whether the valve is open or closed. This feature is particularly useful in applications where quick identification of the valve’s position is critical. However, rising stem valves require more vertical space for operation, making them less suitable for confined areas.

- Non-Rising Stem Gate Valves: These valves are more compact and do not require additional vertical space for operation. The stem remains stationary, and the gate moves internally. This design is ideal for underground installations or areas with limited space. However, since the stem does not move, it is harder to visually determine the valve’s position, which can be a drawback in some applications.

Choosing between the two depends on factors like installation space, the need for visual indication, and the specific requirements of the system.

Summary

The stem of a valve is a vital component that ensures proper operation and control of fluid flow. Whether it’s a rising stem or a non-rising stem gate valve, understanding the differences and applications of each type can help you make the right choice for your needs. By selecting high-quality valve stems, you can avoid operational issues, reduce downtime, and ensure long-term reliability.

Choose IVALVECRAFT, choose a reliable partner, enjoy high quality and the best service.