Are you struggling to understand what a manifold is and how it impacts your plumbing, heating, or industrial systems? This confusion can lead to poor decision-making, faulty installations, and even costly repairs. The problem becomes even more serious when performance is compromised, leading to delays, system failures, and increased maintenance costs. Fortunately, understanding the purpose and function of a manifold can help you avoid these issues and make more informed decisions.

A manifold is a device used to distribute or collect fluid in piping systems. It plays a critical role in many systems, including heating, cooling, and water distribution. Understanding how manifolds work can help you optimize system performance and ensure reliable operation.

In this article, we will break down the different types of manifolds, their applications, and how they function in various industries, so you can make more informed decisions for your projects.

What Is the Purpose of a Manifold?

A manifold is a crucial component in various systems, most commonly in heating, plumbing, and industrial processes. It serves as a central hub for the distribution or collection of fluids, such as water, steam, oil, or gas. The manifold allows for better control over the flow and pressure of these fluids, ensuring efficiency, safety, and reliability.

In heating systems, for example, a manifold connects multiple radiators to the central heating circuit. It ensures a consistent flow of hot water to each radiator, helping maintain an even temperature throughout the building. In industrial settings, manifolds are used to manage the flow of liquids or gases through a series of pipes or machines, optimizing performance and reducing the chances of blockages or leaks.

In simpler terms, manifolds help control how fluids move through a system, making them essential for both residential and industrial applications. Without manifolds, it would be challenging to manage fluid distribution effectively.

What Does Manifold Mean in the UK?

In the UK, the term “manifold” generally refers to a component used in a variety of systems, such as plumbing, heating, and automotive engineering. While the specific design and use of a manifold can vary, the core function remains the same: it is a device that helps distribute or collect fluids across multiple channels.

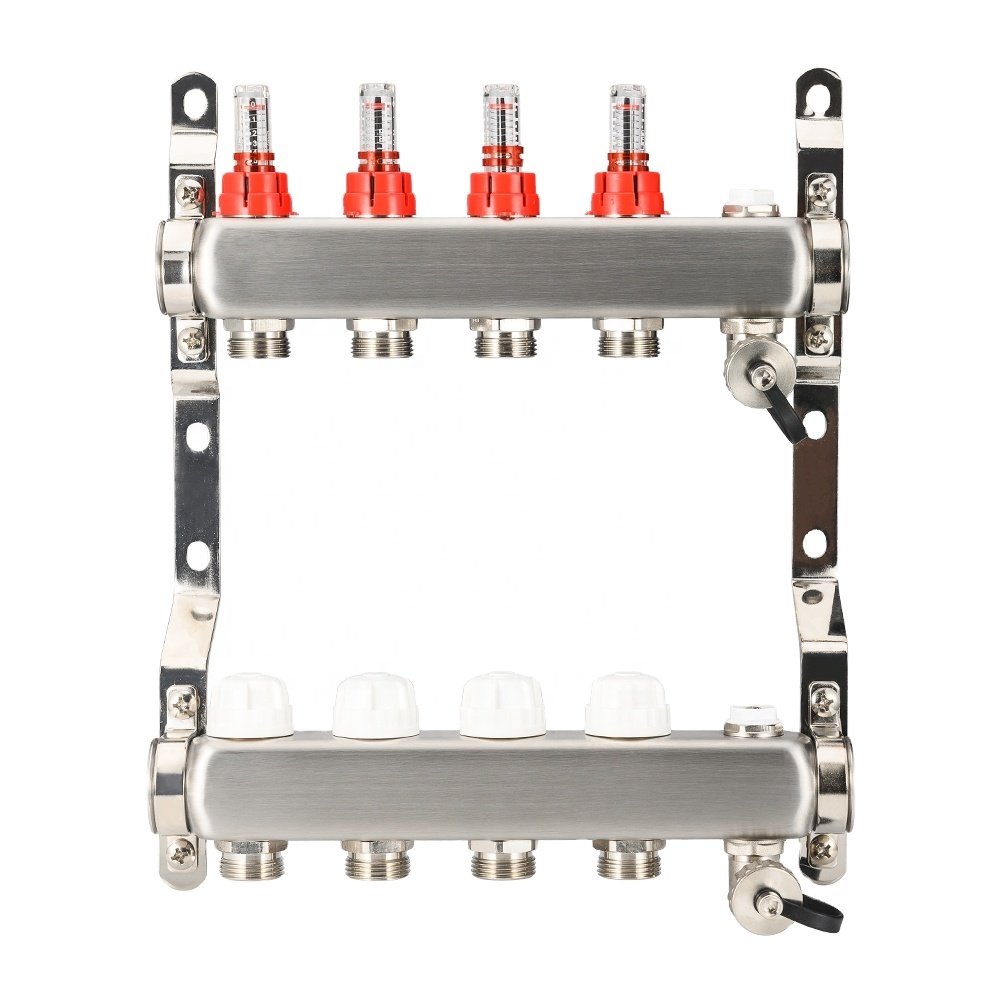

For example, in UK plumbing systems, manifolds are typically used in underfloor heating systems, where they distribute hot water to various loops of piping. These manifolds are designed to ensure an even distribution of heat across the floor, creating a comfortable and efficient heating environment.

In the automotive industry, a manifold refers to an intake or exhaust manifold that connects the engine’s cylinders to the intake or exhaust system. This helps regulate the flow of air or exhaust gases to improve engine efficiency.

Thus, whether you’re dealing with heating, plumbing, or automotive systems, a manifold in the UK serves the same purpose of optimizing fluid flow, ensuring safety and reliability.

What Is a Manifold in Piping?

In piping systems, a manifold serves as a junction point where multiple pipes converge or diverge to control the flow of fluids. Manifolds are used to divide a single flow of fluid into several separate flows or to combine multiple fluid lines into one. This is particularly useful in systems that require complex fluid distribution, such as in heating or water distribution systems.

For example, in a heating system, a manifold allows hot water to flow from a central boiler to multiple radiators. Each radiator is connected to the manifold, ensuring that each unit receives the correct amount of water, maintaining an even temperature throughout the building. In a plumbing system, a manifold may be used to direct water to different areas of the house, such as kitchens, bathrooms, and laundry rooms.

In industrial applications, manifolds are used to manage the flow of gases, oils, or other fluids. By allowing for precise control over fluid distribution, manifolds help prevent overpressure, reduce waste, and ensure the system operates efficiently.

What Is a Manifold in a Ship?

In a maritime context, a manifold plays a similar role but is designed to handle the unique challenges of operating on a ship. It is primarily used in fuel and oil distribution systems, as well as in the ship’s cooling and heating systems. Manifolds on ships are responsible for distributing fuel to various engines or machinery, ensuring that each engine gets the right amount of fuel at the correct pressure.

Manifolds on ships are typically made from durable materials, such as brass, to withstand the corrosive effects of seawater and the high-pressure demands of marine engines. Additionally, they help regulate the flow of fuel and oil, ensuring smooth and efficient operation of the ship’s machinery.

On some ships, manifolds are also used in ballast systems, where they control the flow of water into and out of ballast tanks. This helps maintain the ship’s stability and ensures that it is properly balanced during transit.

Whether it’s managing fuel or controlling water flow, manifolds in ships are essential for maintaining safe and efficient operations at sea.

What Is a Differential Manifold?

A differential manifold is a mathematical concept used in fields like geometry and physics, particularly in the study of curved spaces. While this might seem far removed from the world of plumbing or heating systems, the concept of a manifold is rooted in geometry. In a differential manifold, local regions resemble Euclidean space, meaning they can be studied with the same methods as flat surfaces. This term is more relevant for those working in theoretical fields but shares the fundamental idea of connecting and distributing different components in a system.

In practical applications, the “manifold” you’re likely dealing with is a physical component that distributes fluids, whereas a differential manifold is a more abstract concept related to space and curvature.

Summary

A manifold is an essential component in plumbing, heating, industrial, and even marine systems. Whether it’s distributing water, fuel, or steam, manifolds help ensure that fluid flows efficiently and reliably throughout the system. Understanding how manifolds work and their various applications can lead to better system performance, reducing maintenance costs and avoiding costly failures.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.