When it comes to plumbing and heating systems, one common pain point is the failure of valves, leading to leaks, pressure drops, and even system breakdowns. These issues can cause significant damage, costly repairs, and downtime. The solution? A reliable brass ball valve. Known for its durability and efficiency, a brass ball valve ensures smooth operation, preventing leaks and maintaining stable pressure. This article will explore the uses, benefits, and key differences of brass ball valves, helping you make an informed decision for your systems.

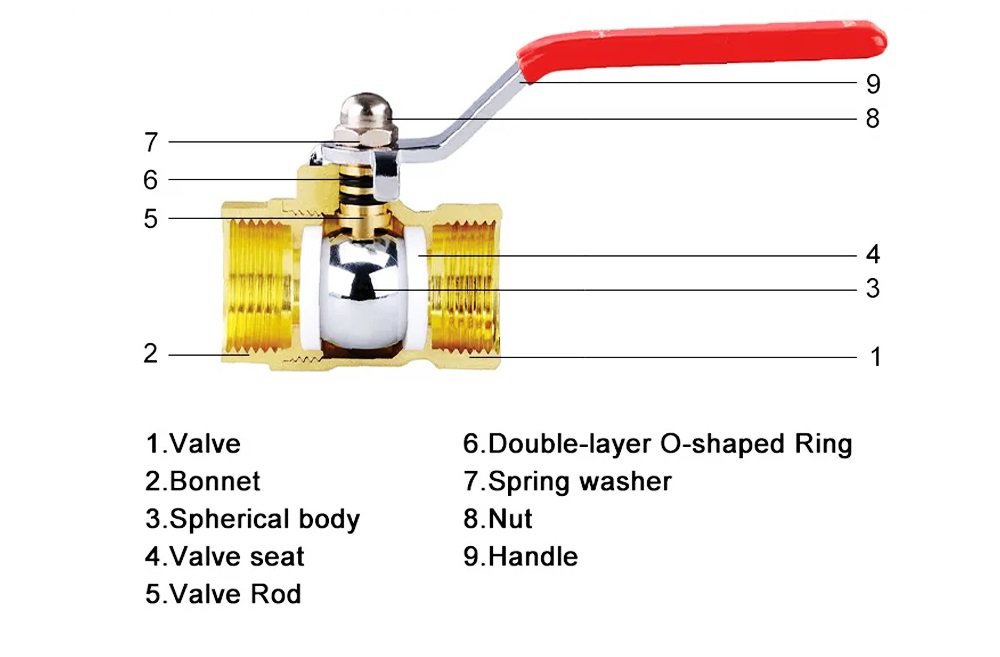

A brass ball valve is a type of quarter-turn valve used to control the flow of liquids or gases in plumbing, heating, and industrial systems. It features a spherical disc (the ball) with a hole through it, which allows for precise flow control when rotated. Brass ball valves are widely used due to their durability, corrosion resistance, and ability to handle high pressure and temperature.

Curious to learn more about brass ball valves and how they can benefit your systems? Keep reading to discover the differences between brass and bronze ball valves, how to operate them, and how they compare to other valve types like needle valves.

What is the Difference Between Brass and Bronze Ball Valves?

Brass and bronze ball valves are both popular choices for plumbing and industrial applications, but they have distinct differences. Brass ball valves are made from an alloy of copper and zinc, making them highly resistant to corrosion and ideal for water-based systems. They are also more affordable and easier to machine, which makes them a cost-effective option for many applications.

On the other hand, bronze ball valves are made from an alloy of copper and tin, sometimes with additional elements like aluminum or nickel. Bronze valves are known for their superior strength and resistance to harsh environments, such as seawater or chemical exposure. However, they are typically more expensive than brass valves.

In summary, if you need a valve for standard water systems or general-purpose applications, a brass ball valve is a reliable and economical choice. For more demanding environments, such as marine or chemical industries, a bronze ball valve might be the better option.

How to Open a Brass Ball Valve?

Opening a brass ball valve is a straightforward process, but it’s essential to do it correctly to avoid damage. Here’s a step-by-step guide:

- Identify the Valve Handle: The handle is usually a lever or a knob attached to the top of the valve. When the handle is parallel to the pipe, the valve is open. When it’s perpendicular, the valve is closed.

- Turn the Handle: To open the valve, turn the handle 90 degrees (a quarter turn) so that it aligns with the pipe. This action rotates the ball inside the valve, allowing the flow of liquid or gas.

- Check for Flow: Once the handle is in the open position, check the system to ensure that the fluid or gas is flowing as expected.

- Avoid Over-Tightening: When closing the valve, turn the handle back to its original position without applying excessive force. Over-tightening can damage the valve or cause leaks.

By following these steps, you can ensure the proper operation of your brass ball valve and extend its lifespan.

What is Ball Valve vs Needle Valve?

Ball valves and needle valves are both used to control the flow of fluids, but they serve different purposes and have distinct designs. A ball valve uses a spherical disc to control flow. When the hole in the ball aligns with the pipe, the valve is open, allowing full flow. When the ball is rotated 90 degrees, the valve closes, blocking the flow completely. Ball valves are ideal for applications requiring quick shut-off and minimal pressure drop.

In contrast, a needle valve uses a slender, tapered needle-like plunger to control flow. The plunger fits into a small seat, allowing for precise flow regulation. Needle valves are commonly used in applications where fine control over flow rate is needed, such as in instrumentation or calibration systems.

While ball valves are better for on/off control and high-flow applications, needle valves excel in situations requiring precise adjustments. Choosing the right valve depends on your specific needs and system requirements.

Summary

Brass ball valves are versatile, durable, and essential components in plumbing, heating, and industrial systems. They offer excellent corrosion resistance, ease of operation, and reliable performance. Whether you’re comparing brass and bronze ball valves, learning how to operate them, or deciding between ball valves and needle valves, understanding their features and applications is key to making the right choice.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.