Are you struggling with inconsistent water temperatures in your heating or plumbing systems? Unstable temperatures can lead to discomfort, safety hazards, and even damage to your equipment. The solution? A tempering valve. This small but crucial device ensures a steady, safe water temperature, protecting your systems and providing peace of mind. Keep reading to learn how a tempering valve can solve your temperature control problems.

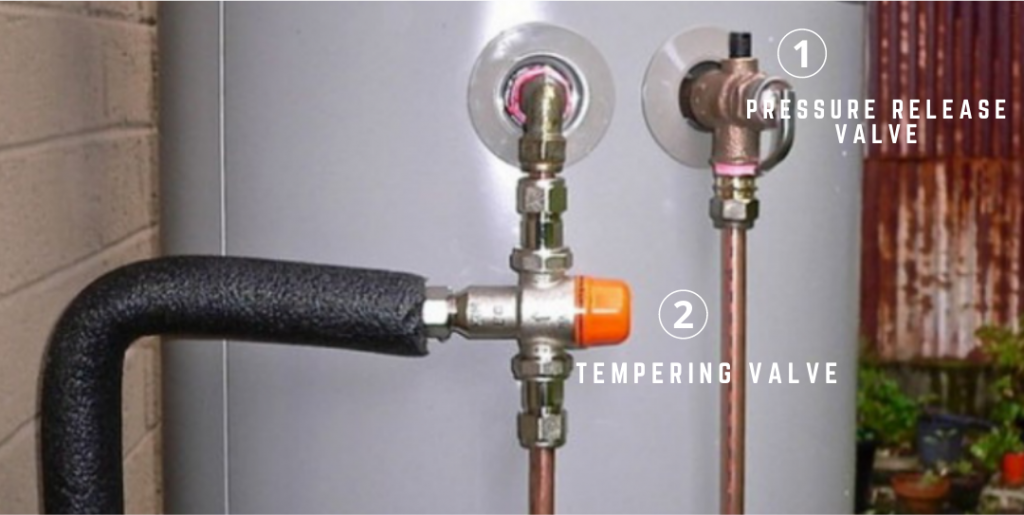

A tempering valve is a thermostatic device that blends hot and cold water to deliver a consistent, safe outlet temperature. It is commonly used in boilers, water heaters, and sinks to prevent scalding and ensure optimal performance.

Curious to know more about how a tempering valve works and why it’s essential for your systems? Let’s dive deeper into its functions, differences from mixing valves, and temperature limits.

What is a Tempering Valve?

A tempering valve plays a critical role in maintaining safe and consistent water temperatures in various applications, such as tempering valves for boilers, water heaters, and sinks. It works by blending hot and cold water to achieve a pre-set outlet temperature, ensuring that the water is neither too hot nor too cold. This is especially important in environments where safety is a priority, such as hospitals, schools, and homes with young children or elderly residents.

For example, a tempering valve for a water heater prevents scalding by limiting the maximum temperature of the hot water supply. Similarly, a drain tempering valve ensures that wastewater is cooled to a safe temperature before being discharged into the drainage system. By providing precise temperature control, tempering valves enhance safety, improve energy efficiency, and extend the lifespan of your plumbing and heating systems.

What is the Difference Between a Tempering Valve and a Mixing Valve?

While both tempering valves and mixing valves regulate water temperature, they serve different purposes and operate in distinct ways. A tempering valve is designed to deliver a safe, consistent outlet temperature by blending hot and cold water. It is typically used in applications where safety is the primary concern, such as preventing scalding in domestic hot water systems.

On the other hand, a mixing valve is more versatile and is often used in heating systems to control the temperature of water circulating through radiators or underfloor heating. Mixing valves can adjust the temperature based on external inputs, such as room thermostats, making them ideal for maintaining comfort in different zones of a building.

In summary, tempering valves focus on safety and consistency, while mixing valves prioritize comfort and flexibility. Choosing the right valve depends on your specific needs and application.

What is the Maximum Temperature for a Tempering Valve?

The maximum temperature for a tempering valve depends on its design and intended use. Most tempering valves are set to deliver water at a safe temperature range of 38°C to 50°C (100°F to 122°F). This range is ideal for domestic applications, as it minimizes the risk of scalding while providing comfortable hot water for daily use.

However, some tempering valves can handle higher temperatures for industrial or commercial applications. For instance, a tempering valve for a boiler might be set to a higher maximum temperature to meet the demands of a large-scale heating system. It’s crucial to select a valve with the appropriate temperature range for your specific application to ensure safety and efficiency.

Conclusion

A tempering valve is an essential component for maintaining safe and consistent water temperatures in various systems. Whether you need a tempering valve for a water heater, boiler, or sink, this device ensures optimal performance and safety. By understanding its functions, differences from mixing valves, and temperature limits, you can make informed decisions for your plumbing and heating needs.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.