Installing a ball valve incorrectly can lead to leaks, reduced efficiency, or even system failure. These issues can cause costly repairs, downtime, and frustration. But don’t worry—proper installation is easier than you think. By following the right steps and avoiding common mistakes, you can ensure your ball valve operates smoothly for years. Let’s dive into the details to make your installation process seamless.

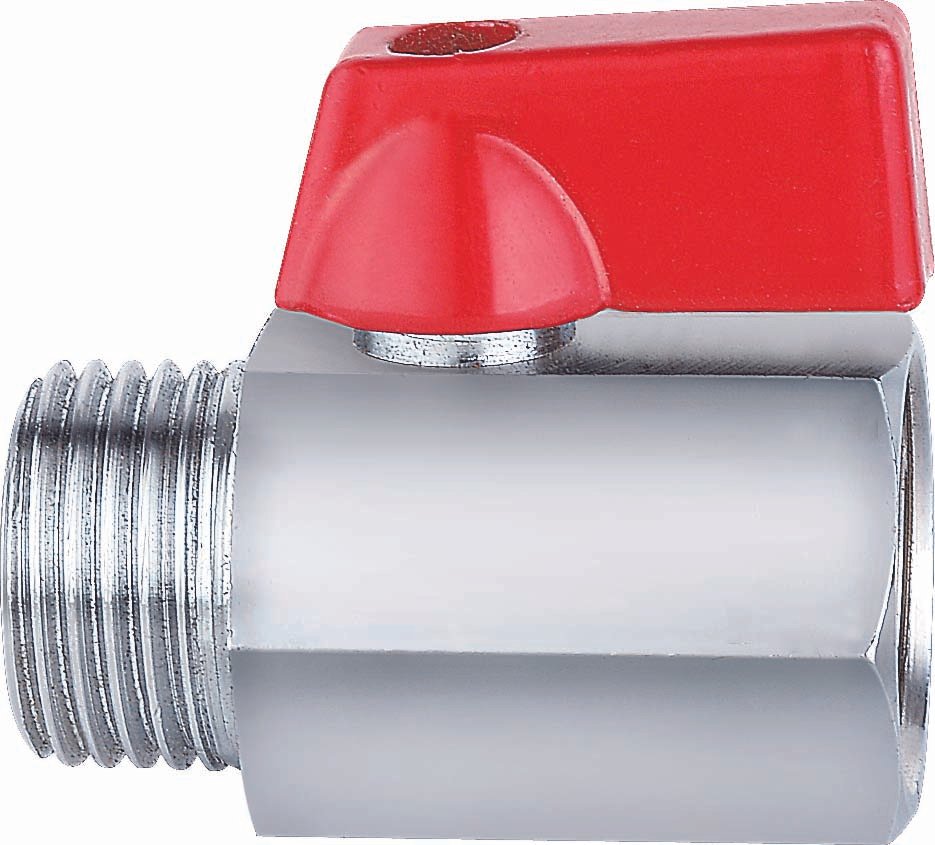

A ball valve should be installed by ensuring proper alignment, correct orientation, and secure connections. For threaded brass ball valves or sweat brass ball valves, use appropriate sealing methods like Teflon tape or solder. Always check for leaks after installation to ensure optimal performance.

Understanding the correct way to install a ball valve is crucial for maintaining the efficiency and longevity of your plumbing or heating system. Whether you’re working with stainless steel ball valves or brass ball valves, this guide will walk you through the process step by step.

Is There a Wrong Way to Install a Ball Valve?

Yes, there are several common mistakes people make when installing ball valves. One of the most frequent errors is improper sealing. For threaded brass ball valves, failing to use Teflon tape or pipe dope can result in leaks. Similarly, for sweat brass ball valves, insufficient soldering can lead to weak connections.

Another mistake is forcing the valve into place. Ball valves, whether male-female or threaded, should fit snugly without excessive pressure. Over-tightening can damage the threads or deform the valve, compromising its functionality. Additionally, installing the valve in the wrong orientation can restrict flow or cause operational issues.

Lastly, neglecting to check for leaks after installation is a critical oversight. Even a small leak can escalate into a major problem over time, especially in high-pressure systems. Always perform a thorough inspection and test run to ensure everything is working correctly.

What Is the Orientation of Valve Installation?

The orientation of a ball valve is crucial for its proper operation. Most ball valves are designed to be installed horizontally, with the handle positioned for easy access. This orientation ensures smooth operation and allows for quick shut-off in case of emergencies.

However, the specific orientation can vary depending on the type of valve and its application. For example, stainless steel ball valves used in industrial settings might have different requirements compared to brass ball valves used in residential plumbing. Always refer to the manufacturer’s guidelines to determine the correct orientation for your specific valve.

In some cases, the valve body may have an arrow indicating the flow direction. Make sure to align this arrow with the direction of the fluid flow in your system. Incorrect alignment can lead to reduced efficiency and potential damage to the valve.

Can a Ball Valve Be Installed Vertically?

Yes, a ball valve can be installed vertically, but there are some considerations to keep in mind. Vertical installation is often used in tight spaces where horizontal installation isn’t feasible. However, not all ball valves are designed for vertical installation, so it’s essential to check the manufacturer’s specifications.

When installing a ball valve vertically, ensure that the handle is accessible and can be easily operated. For threaded brass ball valves or sweat brass ball valves, make sure the connections are secure and leak-free. Vertical installation can sometimes cause stress on the valve, so regular maintenance and inspection are crucial to prevent issues.

Additionally, consider the type of fluid flowing through the valve. In some cases, vertical installation can lead to sediment buildup, which might affect the valve’s performance. Installing a filter upstream can help mitigate this problem.

Summary

Proper installation of a ball valve is essential for ensuring the efficiency and longevity of your plumbing or heating system. Whether you’re working with stainless steel ball valves, brass ball valves, or any other type, following the correct steps and avoiding common mistakes can save you time and money. Always refer to the manufacturer’s guidelines and perform thorough checks to ensure everything is in order.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.