Have you ever faced issues with inconsistent water temperatures or sudden scalding from your taps? These problems often stem from a faulty tempering valve, which can lead to discomfort, safety hazards, and even costly repairs. The good news is, regular maintenance and timely replacement of your tempering valve can prevent these headaches. In this article, we’ll guide you through everything you need to know about tempering valve replacement and maintenance.

A tempering valve should typically be replaced every 5 to 10 years, depending on usage and water quality. Regular inspections can help identify wear and tear early, ensuring optimal performance and safety.

Curious to learn more about how to keep your tempering valve in top condition? Keep reading as we dive deeper into the specifics of tempering valves, including their lifespan, maintenance requirements, and key considerations for replacement.

What Is the Maximum Temperature for a Tempering Valve?

Tempering valves are designed to regulate water temperature, ensuring it stays within a safe and comfortable range. The maximum temperature for a tempering valve is usually set at 50°C (122°F) for domestic use, as recommended by most safety standards. This temperature is ideal for preventing scalding while still providing comfortably hot water for daily activities like showering or washing dishes.

However, in some commercial or industrial settings, the maximum temperature may vary depending on specific requirements. For instance, hospitals or childcare facilities might set their tempering valves to a lower temperature to ensure extra safety. It’s crucial to check local regulations and standards to determine the appropriate temperature setting for your application.

When selecting a tempering valve, consider factors like water pressure, flow rate, and compatibility with your plumbing system. High-quality valves, like those offered by IVALVECRAFT, ensure consistent performance and durability, even under demanding conditions.

Are Tempering Valves Mandatory in NZ?

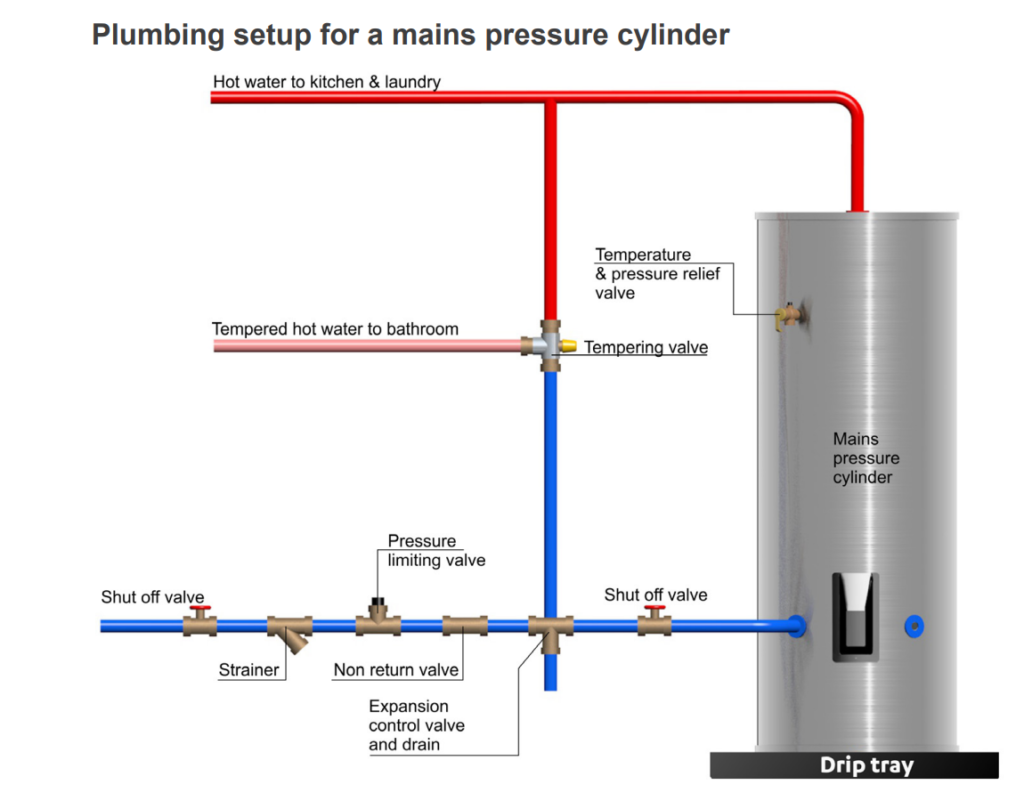

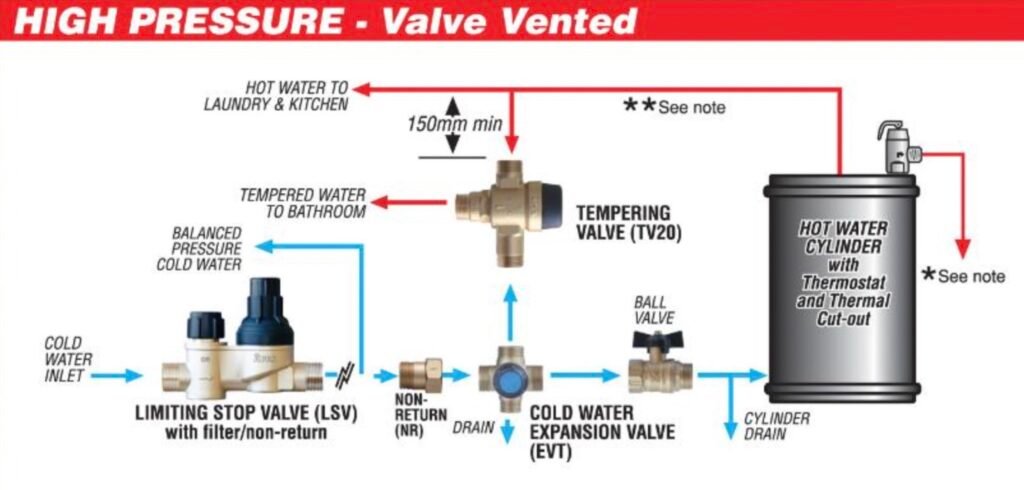

In New Zealand, tempering valves are mandatory for all new installations and renovations where hot water is supplied to bathrooms, laundries, and other areas accessible to the public. This regulation is part of the New Zealand Building Code, which aims to prevent scalding injuries, especially among vulnerable groups like children and the elderly.

The code specifies that hot water delivered to these areas must not exceed 55°C (131°F). Tempering valves play a critical role in achieving this by mixing hot and cold water to maintain a safe temperature. Failure to comply with these regulations can result in fines or legal liabilities, making it essential to install and maintain high-quality tempering valves.

For businesses and homeowners in NZ, investing in reliable tempering valves not only ensures compliance but also enhances safety and comfort. IVALVECRAFT’s range of thermostatic mixing valves is designed to meet these stringent standards, offering peace of mind and long-term reliability.

Do Tempering Valves Need to Be Serviced?

Yes, tempering valves require regular servicing to ensure they function correctly and maintain safety standards. Over time, mineral deposits, sediment, and wear can affect the valve’s performance, leading to issues like inconsistent water temperatures or complete failure.

Servicing a tempering valve typically involves:

- Inspecting for leaks or damage.

- Cleaning internal components to remove buildup.

- Testing the valve to ensure it maintains the correct temperature.

It’s recommended to have your tempering valve serviced by a licensed plumber at least once a year. Regular maintenance not only extends the valve’s lifespan but also prevents costly repairs or replacements down the line.

For those looking to minimize maintenance efforts, choosing high-quality valves like those from IVALVECRAFT can make a significant difference. Our products are designed for durability and ease of maintenance, ensuring reliable performance even in demanding environments.

Summary

Tempering valves are essential for maintaining safe and consistent water temperatures in both residential and commercial settings. By understanding their maximum temperature settings, regulatory requirements, and maintenance needs, you can ensure optimal performance and safety. Regular inspections and timely replacements, ideally every 5 to 10 years, are key to avoiding issues like scalding or system failures. For high-quality tempering valves that meet international standards, explore IVALVECRAFT’s range of products today.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.