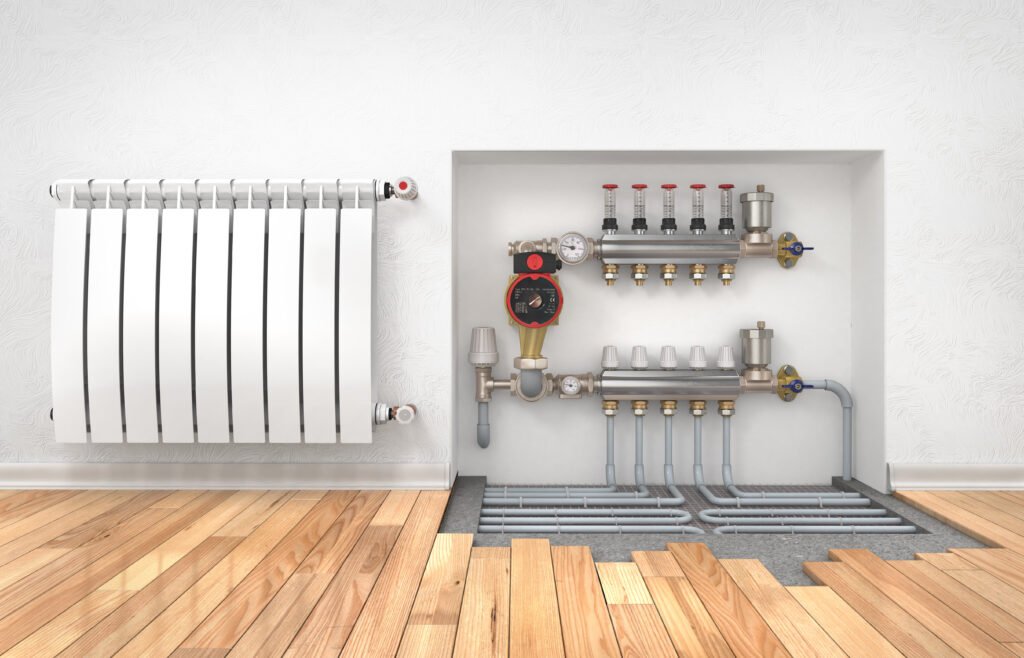

When installing underfloor heating systems, one critical component often causes confusion: the manifold. Improper connection of manifold pipes can lead to poor system performance, uneven heating, and even system failure. If the manifold isn’t installed or connected correctly, it can create pressure imbalances and inefficient heating, which could result in higher energy costs and dissatisfied customers. So how do you connect manifold pipes properly to avoid these issues? Read on to find out how to ensure smooth installation and long-lasting system performance.

Connecting manifold pipes requires careful placement, correct pipe connections, and attention to flow balance. This process ensures your underfloor heating system functions efficiently and avoids potential issues like inconsistent heat distribution and pressure problems.

Now that you understand the importance of proper manifold pipe connections, let’s dive deeper into the essential factors you need to consider for flawless installation.

Where should an underfloor heating manifold be placed?

Choosing the right location for your underfloor heating manifold is crucial to ensuring optimal performance. Ideally, the manifold should be placed in an easily accessible area so that maintenance and future adjustments are simple. Typically, it’s located in a utility room, a cupboard, or a basement. The location should be central to the areas being heated to ensure even distribution of water to all zones.

The manifold should be positioned close to the heat source, such as the boiler or heating pump, but not too close to avoid heat interference. Placing the manifold too far away can cause delays in response times, potentially lowering efficiency. Ideally, a manifold should be placed at a height that allows for easy adjustments and monitoring.

Many professionals recommend placing the manifold at around 300-500 mm above the floor, which allows technicians to access the controls without needing to bend over too much. The closer the manifold is to the heat source, the better the flow rate and the faster the system can respond to changes in heating demand. This can significantly impact the overall performance of the system.

How deep should underfloor heating manifold be?

The depth at which you install the manifold depends on the layout of your underfloor heating system and the space available. Generally, the manifold itself is installed within a wall or a cupboard, but the depth of installation is essential for both practical and aesthetic reasons.

Most installers recommend that the manifold should be recessed into the wall at least 100-150 mm deep, ensuring that it remains protected from any external damage while still being accessible for operation and adjustments. This depth also prevents the manifold from protruding too much into living areas, making it visually less obtrusive.

While it’s tempting to place the manifold in tight spaces, avoid recessing it too deeply, as this could make future maintenance more challenging. The key is finding a balance between keeping the manifold out of sight and ensuring it remains accessible for service when needed.

Can you run underfloor heating without a manifold?

Running underfloor heating without a manifold is technically possible, but it’s highly discouraged and not recommended. A manifold is essential for distributing water evenly across different loops in the heating system. Without a manifold, you would need to create custom pipe layouts, which is a difficult task and often results in inefficient heat distribution.

In the absence of a manifold, the water flow would be much harder to regulate, and you could end up with areas of the floor that are either too hot or too cold. This uneven heating can lead to poor comfort levels and higher energy consumption, as the system would need to work harder to balance temperature discrepancies.

Additionally, the manifold allows for individual control of each loop, providing flexibility in adjusting heating zones. Without it, you lose this control, making the system much less efficient and harder to manage. Therefore, to ensure a smooth, efficient, and reliable underfloor heating system, a manifold is a non-negotiable component.

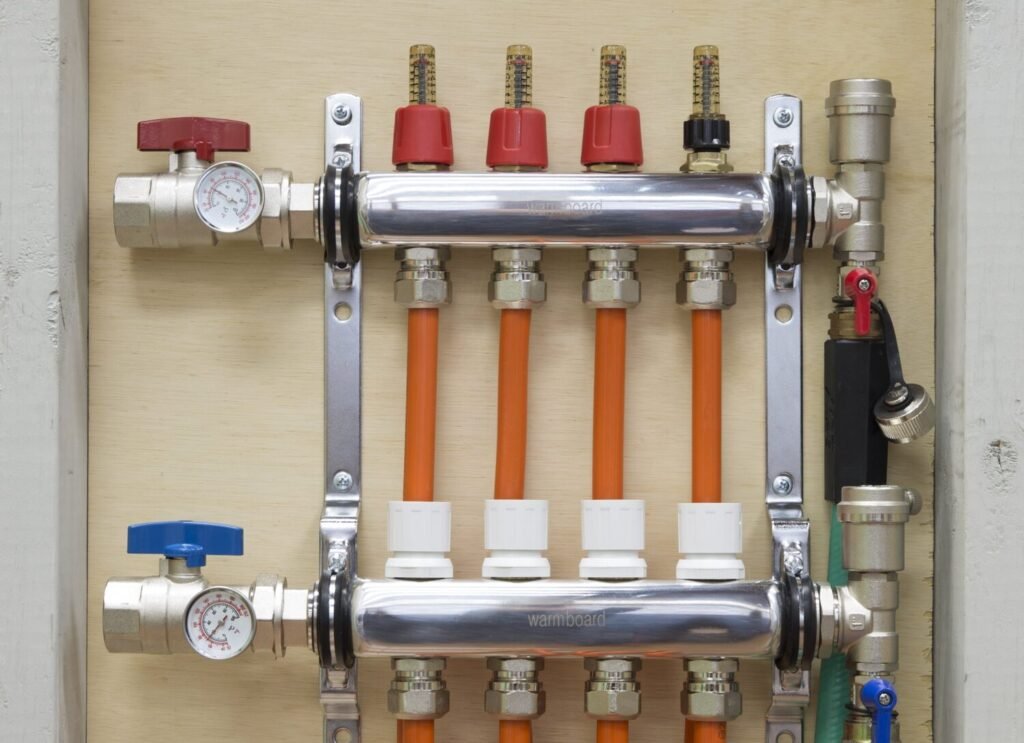

What is the best height for underfloor heating manifolds?

The best height for installing an underfloor heating manifold is usually between 300 mm and 500 mm from the floor level. This height range provides optimal access for the homeowner or technician when adjustments need to be made to the system, such as balancing the flow rates or checking for airlocks.

The height of the manifold plays a crucial role in both its functionality and accessibility. Too high, and it might be difficult for anyone to adjust the valves or read the gauges. Too low, and it might be hard to access, especially if you need to make changes or repairs. Additionally, placing the manifold at the wrong height could interfere with the layout of the floor insulation and underfloor heating pipes, which might cause issues with heating efficiency.

Keeping the manifold at a comfortable height ensures smooth operation and reduces the risk of any unnecessary strain during regular maintenance. It’s worth noting that this height can be adjusted depending on the specific building layout and the system requirements, but it’s essential to strike a balance between practical access and proper functionality.

Where is the manifold located in a house?

In most homes, the manifold is usually located in a central part of the building. This is often near the boiler or pump system, making it easier for the water to flow through the manifold to various zones. Common locations include utility rooms, basements, garages, or even kitchen cupboards if there’s sufficient space.

When choosing a location for the manifold, it’s essential to consider both accessibility and practicality. The manifold should not be placed in areas where it could be damaged, exposed to moisture, or obstructed by other items. In multi-story homes, the manifold may be placed on the ground floor or basement, with the pipes running to various zones on upper levels. This ensures even distribution of the heating water without complicated or inefficient pipe routing.

For larger installations, multiple manifolds might be used, especially if the heating system spans several floors. The goal is to ensure that the manifold’s location allows for easy monitoring and maintenance while also optimizing water flow to the underfloor heating system throughout the house.

Summary

Connecting manifold pipes correctly is essential to ensuring that your underfloor heating system runs efficiently and delivers consistent, reliable heat. Pay attention to the placement, depth, height, and accessibility of the manifold, and always remember that a manifold is indispensable for distributing heat evenly across your system. With these considerations in mind, you can avoid costly mistakes and enjoy better energy efficiency and comfort for years to come.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.