When it comes to valves, the stem is a critical component that often goes unnoticed—until something goes wrong. A faulty valve stem can lead to leaks, reduced efficiency, and even system failures, causing costly downtime and repairs. For businesses relying on high-performance valves, understanding the valve stem’s role and ensuring its quality is non-negotiable. In this article, we’ll explore what the valve stem is, its functions, and why it matters for your operations.

The valve stem is a crucial part of a valve assembly, located at the center of the valve. It connects the actuator to the valve disc or ball, enabling the control of fluid flow. Without a properly functioning stem, the valve cannot operate effectively.

Curious to learn more about this small but mighty component? Let’s dive deeper into the world of valve stems and uncover their importance in various types of valves.

What is the Stem of a Valve?

The stem of a valve is the component responsible for transmitting motion from the actuator (such as a handle or motor) to the valve’s internal parts, like the disc or ball. It acts as the bridge between the control mechanism and the valve’s flow-regulating elements. In simpler terms, when you turn a valve handle, the stem is what moves the internal parts to open or close the valve.

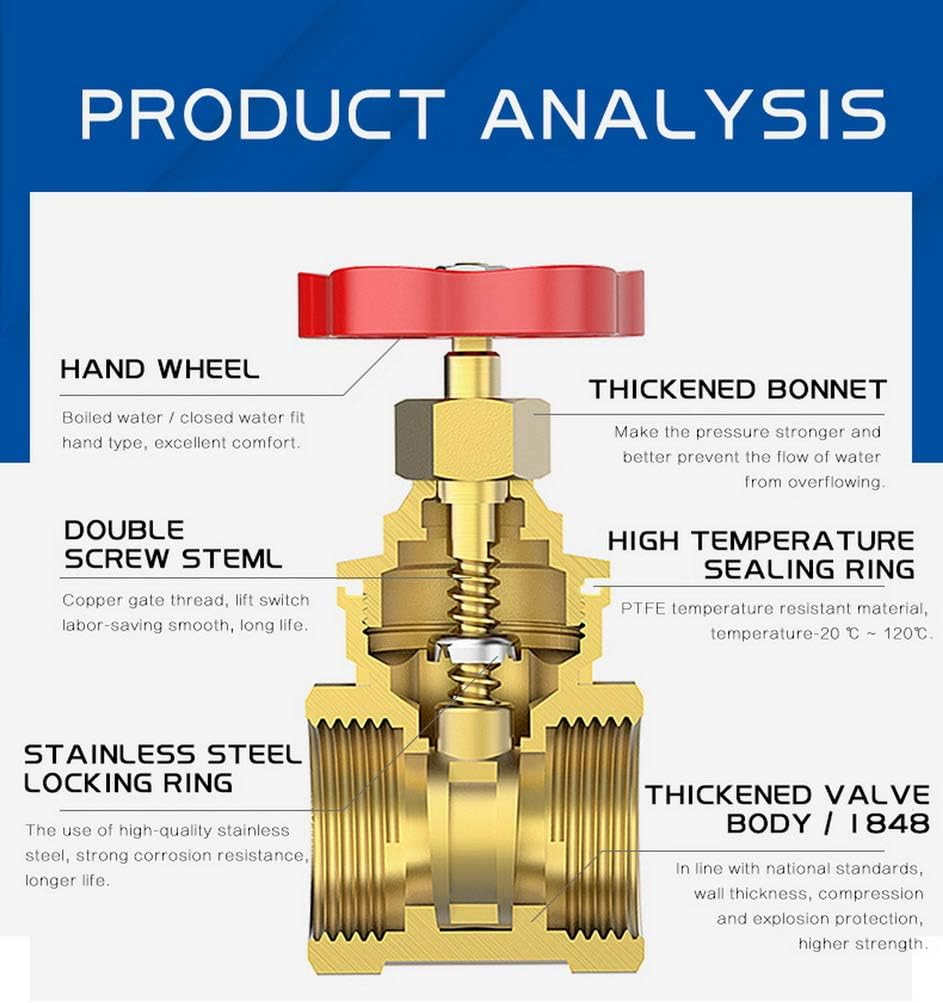

Valve stems are typically made from durable materials like brass, stainless steel, or carbon steel, ensuring they can withstand high pressure and temperature conditions. They are designed to be precise and reliable, as even a small misalignment can lead to leaks or operational failures. In a valve parts diagram, the stem is often highlighted as a central component, emphasizing its importance in the overall assembly.

For industries like plumbing, heating systems, and construction, understanding the stem’s role is essential. It ensures smooth operation, prevents leaks, and maintains system efficiency. Whether you’re dealing with a thermostatic radiator valve or a pressure reducing valve, the stem is the unsung hero that keeps everything running smoothly.

What is the Stem in a Ball Valve?

In a ball valve, the stem plays a slightly different but equally important role. A ball valve uses a spherical disc (the ball) to control flow, and the stem is the component that rotates this ball. When you turn the handle of a ball valve, the stem rotates the ball to either align the hole in the ball with the flow path (open position) or block it (closed position).

The stem in a ball valve is designed to provide a tight seal, preventing leaks even under high pressure. It’s often equipped with seals or O-rings to ensure no fluid escapes around the stem. This makes ball valves highly reliable for applications where leak prevention is critical, such as in heating systems or plumbing networks.

For businesses like yours, sourcing high-quality ball valves with durable stems is crucial. A poorly made stem can lead to operational issues, increased maintenance costs, and even safety hazards. That’s why IVALVECRAFT focuses on delivering brass ball valves with precision-engineered stems, ensuring long-lasting performance and reliability.

What is the Valve Stem or Core?

The valve stem, sometimes referred to as the valve core, is the heart of the valve’s operation. It’s the part that moves up and down or rotates to control the flow of fluid or gas. In some valves, like safety valves or thermostatic mixing valves, the stem is also responsible for regulating pressure or temperature, making it a multifunctional component.

The core’s design varies depending on the valve type. For example, in a control valve, the stem might be connected to a diaphragm or piston to regulate flow precisely. In contrast, in a radiator valve, the stem is often linked to a thermostatic element that adjusts the flow based on temperature changes.

Understanding the valve stem or core is particularly important for industries that rely on precise flow control, such as HVAC systems or industrial manufacturing. A well-designed stem ensures accurate performance, reduces wear and tear, and extends the valve’s lifespan.

Summary

The valve stem may be a small part of the overall valve assembly, but its role is undeniably significant. From controlling flow in ball valves to regulating pressure in safety valves, the stem ensures smooth and efficient operation. For businesses like yours, investing in high-quality valves with durable, precision-engineered stems is key to avoiding operational issues and maintaining system reliability.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.