Have you ever noticed your water temperature suddenly changing, getting too hot or too cold? This could be due to a faulty thermostatic valve. When these valves fail, they cause unstable water temperatures, leading to discomfort, scalding risks, and even damage to plumbing systems. If left unchecked, a malfunctioning thermostatic valve can disrupt heating efficiency, waste energy, and require costly repairs. The good news is that most problems with thermostatic valves can be fixed with proper maintenance and adjustments. In this article, we will explore common issues and how to solve them.

The main problem with thermostatic valves is that they can fail over time due to wear, debris buildup, or incorrect adjustments. This leads to unstable water temperatures, reduced water pressure, and potential scalding risks. Regular maintenance and proper installation can help prevent these issues.

Understanding why thermostatic valves fail and how to fix them is key to maintaining a reliable heating or plumbing system. Below, we will dive deeper into common problems, testing methods, and solutions.

How do you test a thermostatic mixing valve?

Testing a thermostatic mixing valve is essential to ensure that it is functioning properly. If a valve is failing, it may cause water temperature fluctuations, leading to discomfort or safety risks. Here’s how to test a thermostatic mixing valve effectively:

- Turn on the Hot Water

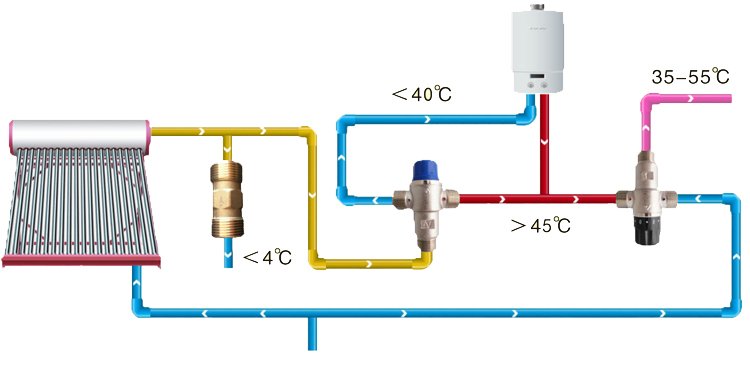

Start by turning on a tap connected to the thermostatic mixing valve. Let the water run for a few minutes to stabilize the temperature. - Measure the Temperature

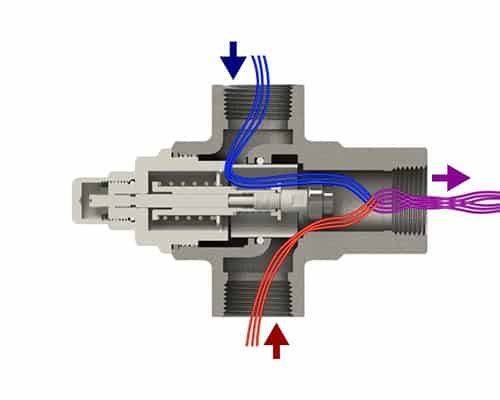

Use a thermometer to check the water temperature. A properly working thermostatic mixing valve should maintain a consistent output, typically between 35-45°C (95-113°F). If the temperature fluctuates or is significantly different from the expected range, the valve may need adjustment or replacement. - Check for Pressure and Flow Issues

If the water pressure is lower than usual, the mixing valve might be clogged with debris or failing internally. Compare the pressure with other taps in the building to identify inconsistencies. - Perform a Cold Water Shut-Off Test

To test if the valve is correctly balancing hot and cold water, shut off the cold water supply while the tap is running. If the valve is functioning properly, the water flow should reduce significantly or stop completely. If hot water continues to flow, the thermostatic mixing valve is not shutting off properly and may need repair. - Adjust the Valve if Necessary

If you suspect the temperature setting is off, you may need to adjust the mixing valve. Locate the adjustment screw or dial (depending on the model) and turn it slightly to modify the temperature. Always retest the water after making adjustments.

Why does the mixing valve fail on my hot water tank?

A thermostatic mixing valve can fail for several reasons, causing inconsistent water temperatures or reduced performance. Below are some of the most common causes of failure:

- Mineral and Debris Buildup

Over time, hard water can cause limescale buildup inside the valve, restricting the proper flow of hot and cold water. This can lead to mixing valve hot water tank problems, such as temperature fluctuations or complete valve failure. - Wear and Tear

Like any mechanical component, a thermostatic mixing valve can wear out over time. Rubber seals, springs, and other internal parts degrade, leading to leaks or inconsistent temperature control. - Incorrect Boiler Mixing Valve Adjustment

If the valve is not correctly adjusted, it may fail to mix water properly. Setting the temperature too high or too low can cause scalding risks or prevent hot water from reaching its intended use. - Blockage in the Water Supply

Dirt, rust, or sediment in the plumbing system can clog the valve, reducing water flow and preventing the thermostatic element from working correctly. - Failure of the Thermostatic Element

The thermostatic element inside the valve is responsible for detecting water temperature and adjusting the mix accordingly. If this element fails, the valve may no longer regulate temperature effectively, leading to extreme fluctuations.

How to Prevent Mixing Valve Failures:

- Regular Cleaning: Flush the valve periodically to remove sediment and buildup.

- Routine Inspections: Check for leaks, pressure changes, and temperature inconsistencies.

- Proper Installation: Ensure the valve is installed according to manufacturer specifications.

- Timely Adjustments: Periodically check and adjust the mixing valve to maintain stable water temperatures.

How do you know if your thermostatic mixing valve is bad?

A faulty thermostatic mixing valve can cause noticeable issues in your plumbing or heating system. Here are some signs that indicate your mixing valve may be failing:

- Inconsistent Water Temperature

If you notice sudden fluctuations in hot and cold water, your thermostatic mixing valve may have gone bad. A properly working valve should maintain a steady output temperature. - Low Water Pressure

A clogged or failing mixing valve can restrict water flow, leading to a noticeable drop in pressure at your taps or shower. - Hot Water Becomes Too Cold

If your hot water isn’t reaching the desired temperature, the valve may be malfunctioning, improperly adjusted, or clogged with debris. - Scalding Water from Faucets or Shower

If you suddenly experience very hot water from a tap, it could mean the mixing valve is no longer properly regulating the temperature. This is particularly dangerous in homes with children or elderly individuals. - Water Flow Stops Suddenly

If your water supply stops completely when adjusting the temperature, it could mean the internal components of the mixing valve have seized up or become blocked. - Difficulty Adjusting the Valve

If turning the adjustment screw or dial doesn’t change the water temperature, the thermostatic element inside the valve might have failed.

Conclusion

Thermostatic mixing valves are crucial for maintaining consistent and safe water temperatures. However, they can develop problems over time due to wear, debris buildup, or incorrect settings. Regular testing, maintenance, and proper mixing valve adjustments can help prevent failures. If you experience fluctuating temperatures, low pressure, or scalding water, it may be time to inspect and service your thermostatic mixing valve. By staying proactive, you can ensure a reliable and efficient hot water system.

Choose IVALVECRAFT, choose reliable partner, enjoy the high quality and best service.